Introduction of different types of movement in pipelines

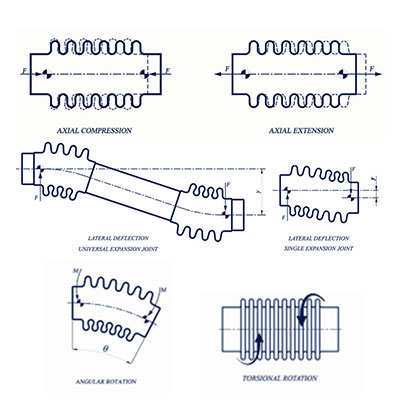

Movement in pipelines includes different types. Before choosing and designing a connection in a correct way, we must know what kind of movements usually occur in the pipeline system. The most important types of movements are axial, angular, lateral, vibrational and twisting. In the following, we will explain these things to you.

Movement examples

- Longitudinal movement: movement in pipelines along the connection axis, which can include stretching and compression, is called longitudinal movement.

- Lateral movement: If the movement created is perpendicular to the axis of the connection, so that one or both ends of the connection move parallel and in the opposite direction, we call it lateral movement. Lateral movement has other names, the most important of which are Parallel Misalignment, Transverse, Lateral Movement, Lateral Offset and Direct Shear.

- Angular movement: If one side of the connection changes its angle and moves radially, it is called angular movement in pipelines. This type of movement is also called ROTATION MOVEMENT. Of course, you should be careful not to confuse this type of movement with a twisting movement. In fact, angular movements are known as permissible movements for joints. Meanwhile, twisting movements are not allowed and only a small part of these movements can cause a lot of tension in the connection and cause it to fail.

- Torsional movement: If one side of the connection rotates with respect to the other side and around its axis, torsional movement occurs. This twist puts a lot of stress on metal accordion blues. For this reason, the designer of the pipeline system must take the necessary measures to prevent this amount of twisting. Be careful not to apply twisting movements to the accordion joints without consulting the manufacturer.

- Vibration movement: Among other types of movement in the pipeline system, vibration can be mentioned. Flexible joints are designed to eliminate vibration caused by compressors, machines, generators, pumps, etc. This vibration can be caused by one or more periodic and simultaneous movements.